1. Bunker Gear Cleaning

2. Bunker Gear Repairing

3. Bunker Gear Inspection

4. Bunker Gear Tracking

5. Rental Bunker Gear

NFPA Repair guarantees a 72 hour turnaround time for cleaning of Personal Protective Equipment. For inspection and repairs the turnaround time will be less than 2 weeks.

Bunker Gear Washing

Bunker gear should be washed once every six months. Cleaning gear more often than this may result in the loss of its fire protective integrity. Washing also has to take place before any repairs can be made. NFPA Repair washes the following garments with a highly specialized wet-wash system.

• Turnout Coats & Pants

• Wildland Brush Gear

• Vests

• Aluminized Coats & Pants

• Station wear shirts

• Station wear pants

• Gloves

• Military One Piece Ensembles (FFE)

• Boots (Rubber & Leather)

• Hoods

• Coveralls

• Helmets

The wet wash process specially developed by NFPA Repair will not degrade the integrity of bunker gear, nor will it void any manufacturer’s warranties. We use the Check6 Aerospace cleaning agent and a state of the art industrial-size washer/extractor. This system deep cleans each bunker garment, and the extractor makes use of an electrically operated valve system, fresh-water-flushing chemical manifold and a six liquid chemical injection point to provide a quality wash while keeping with NFPA 1851 guidelines.

Severe contamination with exposure to elements such as crude oil, may also be cleaned by NFPA Repair. Give us a ring and we will provide you with a competitive free quote. If we can’t clean it, we don’t charge.

Bunker Gear Repair

Certified professional staff is used by NFPA Repair for all repairs and alterations. We are fully trained by leading PPE manufacturers to inspect and repair:

- Velcro enclosures

- Moisture barriers

- Reflective trim and lettering

- Burn holes, rips and tears

- Hardware buttons, snaps zippers, and hooks

- Knee and shoulder pad reinforcements

We adhere to all NFPA standards, and we ensure that rips, tears, burn holes, and other repairs, are done professionally and as quickly as possible. We use flame retardant Nomex and Kevlar for patching and stitching. Repairs to PPE gear made by NFPA Repair will extend the life of bunker gear far beyond what might be expected. We turn older, dirty gear into something resembling the original garment, if not better. Repairing bunker gear is far more cost effective than the purchase of replacement garments. Leading safety protocols as dictated by NFPA regulations are observed at all times.

Customization of Bunker Gear

All firefighting bunker gear is able to be altered by our custom alteration shop staff. Moving a name patch or adding an extra radio pocket is what our custom alteration shop does best. Staff of the custom alteration shop are certified to deal with alterations according to NFPA guidelines.

Inspection of Bunker Gear

NFPA Repair understands that NFPA guidelines dictate how bunker gear has to be regularly inspected. These inspections take place on three levels and our certified staff at NFPA Repair will help carry out these inspections out. The three levels of inspection are:

- Routine Inspection

- Advanced Inspection

- Complete Liner Inspection

Routine Inspection

This inspection is generally carried out by the firefighter who wears the bunker gear. It must take place regularly, and the firefighter is required to search for the following problems:

- Soiling

- Contamination

- Physical damage

- Damage to trim

- Missing trim

- Missing stitches

- Loss of seam integrity

Advanced Inspection

An advanced inspection should take place once every six months according to the NFPA 1851 and NFPA 1871 guidelines. Advanced inspection have to be conducted by a certified third party or personnel in the fire department who are qualified. NFPA Repair plays a vital role in the inspection process, and the following procedures have to be followed:

- Soiled bunker gear must be cleaned before inspection

- Inspection findings must be documented

- All elements of routine inspection to be followed

- Light evaluation of liners

- Leakage evaluation

- Assessment of thermal and physical damage

- Check for missing hardware

- Test moisture barrier integrity

- Test seam integrity

- Test material integrity

- Label integrity test

- Reflectivity test

- Test closure system

Complete Liner Inspection

The complete liner inspection is needed when bunker gear has seen three or more years of wear. This takes place once a year thereafter and the procedure entails:

- Liner being separated from the main body of the garment

- Hidden sides of the moisture barrier and thermal liner are exposed

- Investigation of liner is carried out to test the moisture and water penetration barrier

- Results of these tests must be investigated

- Bunker gear is then either condemned or sewn back together dependent on the results of the test.

- Owner kept notified of the results of the testing

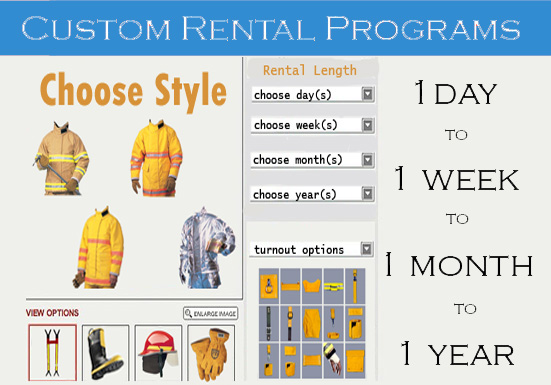

Rental

Bunker Gear

Fire

Gear Rental, a brother

company of NFPA Repair has rental gear for individuals and entire

stations. Give us a ring or visit us online at

www.FireGearRental.com

and we will provide you with a free rental estimate.

|